Sigma-Delta Output

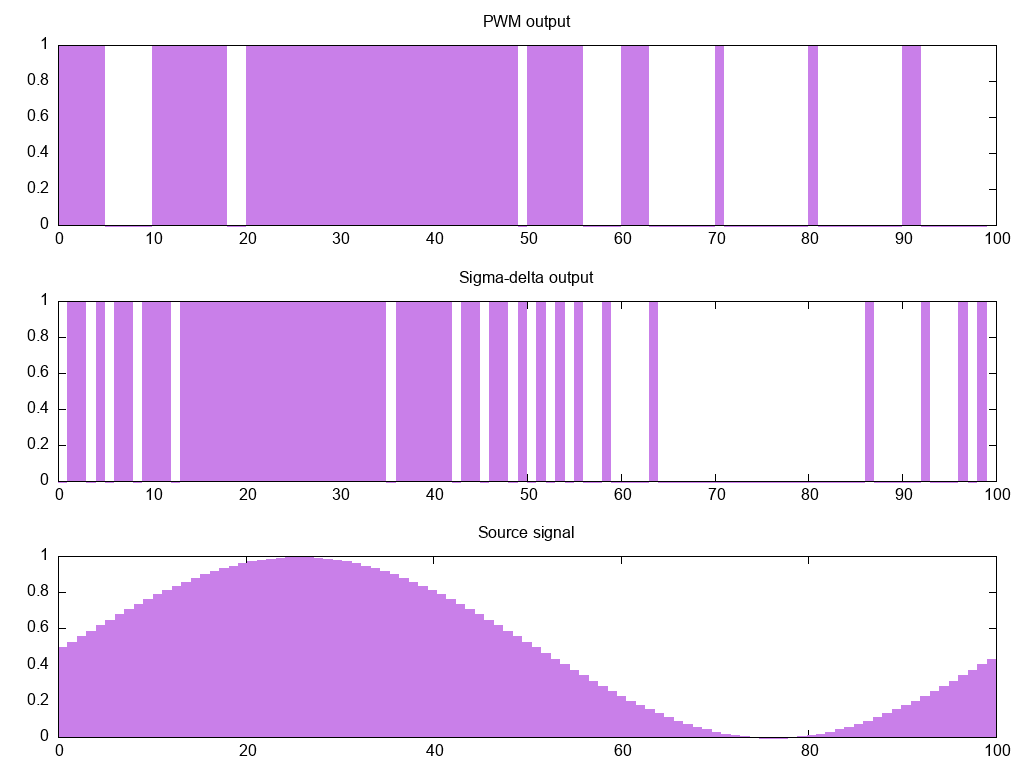

This component uses sigma-delta modulation to output a floating-point value on a binary output. Unlike with Slow PWM Output, it is possible to update the output value with each update cycle, not just at the end of a longer period.

For example, if you choose to toggle the output at most once every 1 second and decide on a PWM period of 10 seconds, for reasonably frequent updates, with Slow PWM Output there are only 10 possible levels, and for higher precision a longer update interval is needed, restricting the update rate.

A sigma-delta output is updated during each cycle, thus a higher precision can be achieved, without being constrained by a calculation timeframe (=period).

So instead of having to define a period where the width of the pulse determines the output level, here you

choose an update_interval which acts like a clock signal from where the pulse density determines the output level.

This component can be used as a drop-in replacement for Slow PWM Output by changing the platform to

sigma_delta_output and changing period to update_interval (you usually want to set the sigma-delta’s

update_interval as a fraction of Slow PWM’s period for similar results)

# Example configuration entry

output:

- platform: sigma_delta_output

update_interval: 10s

id: sd_heater_output

# Output to a pin

pin: GPIOXX

# Use the same output, but through automations

turn_on_action:

then:

- output.turn_on: heater_relay

turn_off_action:

then:

- output.turn_off: heater_relay

- platform: gpio

pin: GPIOXX

id: heater_relayConfiguration variables:

- update_interval (Required, Time): The cycle interval at which the output is recalculated.

- pin (Optional, Pin Schema): The pin to pulse.

- state_change_action (Optional, Automation): An automation to perform when the load is switched. If a lambda is used the boolean

stateparameter holds the new status. - turn_on_action (Optional, Automation): An automation to perform when the load is turned on. Can be used to control for example a switch or output component.

- turn_off_action (Optional, Automation): An automation to perform when the load is turned off.

turn_on_actionandturn_off_actionmust be configured together. - All options from Output.

ℹ️ Note

- If

pinis defined, the GPIO pin state is written before any action is executed.state_change_actionandturn_on_action/turn_off_actioncan be used together.state_change_actionis called beforeturn_on_action/turn_off_action. It’s recommended to use eitherstate_change_actionorturn_on_action/turn_off_actionto change the state of an output. Using both automations together is only recommended for monitoring.

ℹ️ Note

If the output must not be active for more than some fixed time before it has to be off for a while to e.g. cool down, Slow PWM Output should be used with a

max_powersetting to better control the duty cycle.